End of year breaks are nice. Especially when unseasonal weather is about. Usually its snowy and horrible. However this year its been quite fair. Yesterday was 13* and sunny, so I checked the forecast and hauled my tools out to the front of the house to start the Fast90 install.

As Id replaced the injectors before I thought that it would only take a few hours. Id done some reading and the swap and instructions that came with the manifold made it look easy..

Id done some blending of the internal edges and filled some gaps with epoxy, then sanded it all flat and smooth. Nothing major, just a cleanup.

Of course nothing quite goes to plan. Disassembly was easy as you can see below I still have the original LS1 coolant lines under the intake.

There are a few tricky connectors at the rear, but the Holden has reasonable clearance there. You can also lift the manifold forward a little to get better access to the MAP and brake booster line. I did a little cleanup around the intake ports to remove grime too.

Next I needed to remove the coolant lines and replace them with late model plugs and cross over. You can see faintly the rear engine mount on the left, this was to be a pain in the arse.

You also need to remove the clips on the knock sensor wires. I also took off the tape as it was thick and hard, pretty much the same size as the clips. Then replace the valley cover bolts with the button head ones like the pic above. This all helps get the manifold down snug as the floor is lower than stock.

Right time to fit the fast. Cool. Well no, not cool. The problem is that the Fast is longer than the stock manifold and the power steering tank is in the way, worse the rear engine lifting tab is also in the way. It was swearing time. What to do. Well a quick dash inside and a search on

www.ls1gto.com showed me I was not alone. It looked like the rear lift tab had to come off and I needed to space the power steering tank forward. Some guys re-welded their tank mount. But there was no way I was going to be able to get that sorted out over the holiday weekend. So spacers it was. Some cut hands and blood later the rear tab was removed. As expected the last bolt was very hard to get at and getting any heft on it required forcing the open end of the spanner to cut into my hand. Nice.

So rear lifting tab removed, spacers on the front one with the tank mount on it and we are half way there.

The next problem was that the coolant cross over was too high and prevented the intake sitting down nicely on the heads. Out with the hammer and a few blows with the rubber handle had it sitting down enough. Of course violence is not without risk and the pipe got some hairline cracks for its trouble. I mixed up some loctite metal weld and gummed it over the cracks. Fingers crossed on that. (Im planning on an LS7 clutch soon so will get a new cross over with the clutch just in case the current one leaks)

Here is a closeup of the spacers on the front to allow the fuel purge to connect. I just got some M10 bolts from the hardware store and some M12 extra wide nuts to act as the spacers.

All that remained was final assembly and to replace the radiator coolant. You don't need to empty all the coolant out, just enough to empty the fill tank and drop the level below the heads so the cross over pipes don't leak.

All done finished. My over the radiator intake required trimming as well again due to the extra length. Also I think the NW90 is slightly larger in diameter so getting the intake on was tough work. I didnt push it right on as there were some cracking noises starting at that point. Perhaps I will need to dremel out the inside diameter a touch so it slips on better. However it has a sharp raised edge which should stop it slipping off, plus the hose clip.

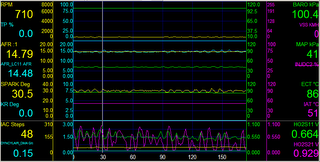

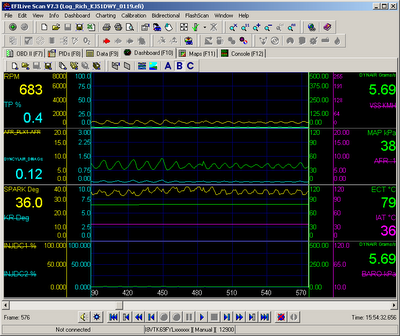

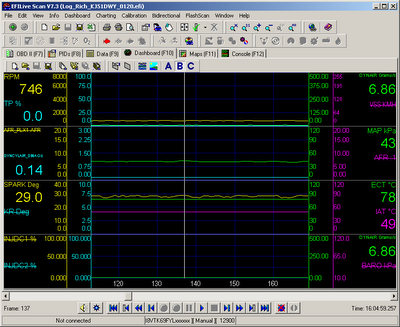

So how does it drive? Well as Im running speed density I will have to relog and adjust VE to compensate so my initial drive showed power much the same. Throttle response as expected with a 90mm throttle was much improved. Im not sure if Im getting clutch slip or loss of rear tyre grip as usually when it brakes traction I get severe axle tramp. More info to follow on the VE gains from the intake.

Oh idle was very close without needing to alter anything over the stock throttle body and intake. Also Ive not yet noticed any issues with leaks which others have had with this intake.

However I think the following things are good to do to minimise the risk of leaks with the Fast.

- Get as much stuff off the valley cover as you can, tape, clips etc (as well as the mandatory coolant pipes)

- Use new intake gaskets. The Fast ones looked a little thicker than the stock ones on the LS6 intake. But that might just be age.

- Make sure if you pull the halves apart you seal them back up well. I used some extra silicon sealant at the joints.