I can report that H0105 is all thats required to sort out Speedo issues noted in my previous post. I Logged a 80Km drive which clocked up only 50Miles on the Odometer.

Ive gone back to stock injectors offsets due to running to rich on low map zero throttle points. In an attempt to kill the richness off I set DFCO to go hardcore on me. Anything under 2% throttle at all map and rpm points. Works ok, but just when it disconnects hitting idle or low RPM to prevent zero fuel stalling you get a jerk. I dont mind too much, but I might readjust this nearer to stock.

I tested Alpha-n fueling, it worked nicely. Very responsive, but AFR didnt track commanded very accurately, it was close. However the feeling it gave was nice and responsive, so I will likely continue with testing.

A diary of the transformation of a couple of HSV Clubsport R8's and various GM V8's

Friday, June 30, 2006

Saturday, June 24, 2006

Diversions

My Speedo has been dead for a month or so. No speed reading, no odometer and no trip computer. A post on ls1.com.au and thanks to motomk I had a wiring diagram and some disassembly instructions. Cool.

I knew the VSS sensor was working as efilive was logging road speed fine, so the problem was somewhere after the pcm. I also knew the speedo needle did work, because going into diagnostic mode the needle would wind up to 80 no problem. From the wiring diagrams I could see that the road speed signal also went to the cruise control system just prior to hitting the instrument display. Ok, so I tested the cruise control and guess what. It worked. I now knew the issue was between there and the speedo.

It was then that I recalled someone posting up an issue with UK spec HSV's basically an aftermarket device was fitted to convert the signal to miles from kilometers and it had problems.

A quick search on pistonheads.com and good old Steve had posted up some info from his VTSS. He had removed the device and resoldered it.

Now I knew what I must do.

Armed with this information I set about pulling the dash apart. First problem, no stereo removal keys. No problem, just bend the stereo bracket to clear the console!

All disassembled and instruments removed. Now where is that evil device!

All disassembled and instruments removed. Now where is that evil device!

Aha, here it is.

Now going into here is a red and black wire. Steve assumed power and ground. Id agree as it comes from a different section of wiring, likely needed to power satans spawn. Out of the device came an orange and green wires. Now thanks to motomk, I knew the wire from the PCM for the speedo was Violet/White, I could see that Violet/Red was cut and rejoined with a short piece of blue wire, no junction just cut. I can only assume the pleb who's job it was to fit these things cut the wrong wire first and had to fix it. So anyway I could see Violet/White was spliced to green which went into the device and orange was spliced into Violet/White up to the instrument connector. Up to this point my intention was to solder up the device to fix any dodgy dry joints and reassemble. However why not just remove it alltogether!? I knew I could use PCM table H0105 to correct the speed signal coming from the PCM, so Id save messing about, increase reliability and gain about a billionth of a second over the 1/4 mile due to the weight reduction, so I thought Id leave it out.

Now going into here is a red and black wire. Steve assumed power and ground. Id agree as it comes from a different section of wiring, likely needed to power satans spawn. Out of the device came an orange and green wires. Now thanks to motomk, I knew the wire from the PCM for the speedo was Violet/White, I could see that Violet/Red was cut and rejoined with a short piece of blue wire, no junction just cut. I can only assume the pleb who's job it was to fit these things cut the wrong wire first and had to fix it. So anyway I could see Violet/White was spliced to green which went into the device and orange was spliced into Violet/White up to the instrument connector. Up to this point my intention was to solder up the device to fix any dodgy dry joints and reassemble. However why not just remove it alltogether!? I knew I could use PCM table H0105 to correct the speed signal coming from the PCM, so Id save messing about, increase reliability and gain about a billionth of a second over the 1/4 mile due to the weight reduction, so I thought Id leave it out.

Here is what Satan's spawn looks like up close and personal. The capacitor next to the incoming wires was broken loose and just wobbled around. If you wanted to fix it, then this would be the repair you needed to do.

So I just reconnected the Violet/White wire together and taped the whole lot back up. Job done.

So I just reconnected the Violet/White wire together and taped the whole lot back up. Job done.

Take it for a test drive. Now reading Km, but not for long. By the way, I dont recommend test driving with just the instruments and not plugging in the power windows, indicators etc when its 28*C outside, it gets kind of hot.

Take it for a test drive. Now reading Km, but not for long. By the way, I dont recommend test driving with just the instruments and not plugging in the power windows, indicators etc when its 28*C outside, it gets kind of hot.

The only thing Im not sure of is how the Odometer will read if I just rely on changing the PCM output signal. Im hoping that given its only one wire that was being messed with and it seemed to handle the odometer as well as trip computer and speed needle, then I will be fine. Worse case Ill have to pull out the dash again and wire Satan's spawn back in place. Ill update in a few days to report what the deal is.

The only thing Im not sure of is how the Odometer will read if I just rely on changing the PCM output signal. Im hoping that given its only one wire that was being messed with and it seemed to handle the odometer as well as trip computer and speed needle, then I will be fine. Worse case Ill have to pull out the dash again and wire Satan's spawn back in place. Ill update in a few days to report what the deal is.

On a more PCM based note. Im now running EFILive custom OS5. It works fine and takes OS3 calibrations. Basically it extends OS3 by adding switchable timing and fueling for NOS applications. You could also use it to pull timing based on a switch for fuel octane variances.

It also supports Alpha-n fueling which is purely determined by Throttle and RPM, no other inputs such as MAF or MAP etc are used. Its really designed for hellish cams that wont hold or give a vacuum or stable airflow reading. (I wish that was me!)

So Ill be likely making some comments on that in the future given thats now my PCM OS d'jour. So its goodbye to OS3 and hello to OS5.

I knew the VSS sensor was working as efilive was logging road speed fine, so the problem was somewhere after the pcm. I also knew the speedo needle did work, because going into diagnostic mode the needle would wind up to 80 no problem. From the wiring diagrams I could see that the road speed signal also went to the cruise control system just prior to hitting the instrument display. Ok, so I tested the cruise control and guess what. It worked. I now knew the issue was between there and the speedo.

It was then that I recalled someone posting up an issue with UK spec HSV's basically an aftermarket device was fitted to convert the signal to miles from kilometers and it had problems.

A quick search on pistonheads.com and good old Steve had posted up some info from his VTSS. He had removed the device and resoldered it.

Now I knew what I must do.

Armed with this information I set about pulling the dash apart. First problem, no stereo removal keys. No problem, just bend the stereo bracket to clear the console!

All disassembled and instruments removed. Now where is that evil device!

All disassembled and instruments removed. Now where is that evil device!Aha, here it is.

Now going into here is a red and black wire. Steve assumed power and ground. Id agree as it comes from a different section of wiring, likely needed to power satans spawn. Out of the device came an orange and green wires. Now thanks to motomk, I knew the wire from the PCM for the speedo was Violet/White, I could see that Violet/Red was cut and rejoined with a short piece of blue wire, no junction just cut. I can only assume the pleb who's job it was to fit these things cut the wrong wire first and had to fix it. So anyway I could see Violet/White was spliced to green which went into the device and orange was spliced into Violet/White up to the instrument connector. Up to this point my intention was to solder up the device to fix any dodgy dry joints and reassemble. However why not just remove it alltogether!? I knew I could use PCM table H0105 to correct the speed signal coming from the PCM, so Id save messing about, increase reliability and gain about a billionth of a second over the 1/4 mile due to the weight reduction, so I thought Id leave it out.

Now going into here is a red and black wire. Steve assumed power and ground. Id agree as it comes from a different section of wiring, likely needed to power satans spawn. Out of the device came an orange and green wires. Now thanks to motomk, I knew the wire from the PCM for the speedo was Violet/White, I could see that Violet/Red was cut and rejoined with a short piece of blue wire, no junction just cut. I can only assume the pleb who's job it was to fit these things cut the wrong wire first and had to fix it. So anyway I could see Violet/White was spliced to green which went into the device and orange was spliced into Violet/White up to the instrument connector. Up to this point my intention was to solder up the device to fix any dodgy dry joints and reassemble. However why not just remove it alltogether!? I knew I could use PCM table H0105 to correct the speed signal coming from the PCM, so Id save messing about, increase reliability and gain about a billionth of a second over the 1/4 mile due to the weight reduction, so I thought Id leave it out.Here is what Satan's spawn looks like up close and personal. The capacitor next to the incoming wires was broken loose and just wobbled around. If you wanted to fix it, then this would be the repair you needed to do.

So I just reconnected the Violet/White wire together and taped the whole lot back up. Job done.

So I just reconnected the Violet/White wire together and taped the whole lot back up. Job done. Take it for a test drive. Now reading Km, but not for long. By the way, I dont recommend test driving with just the instruments and not plugging in the power windows, indicators etc when its 28*C outside, it gets kind of hot.

Take it for a test drive. Now reading Km, but not for long. By the way, I dont recommend test driving with just the instruments and not plugging in the power windows, indicators etc when its 28*C outside, it gets kind of hot. The only thing Im not sure of is how the Odometer will read if I just rely on changing the PCM output signal. Im hoping that given its only one wire that was being messed with and it seemed to handle the odometer as well as trip computer and speed needle, then I will be fine. Worse case Ill have to pull out the dash again and wire Satan's spawn back in place. Ill update in a few days to report what the deal is.

The only thing Im not sure of is how the Odometer will read if I just rely on changing the PCM output signal. Im hoping that given its only one wire that was being messed with and it seemed to handle the odometer as well as trip computer and speed needle, then I will be fine. Worse case Ill have to pull out the dash again and wire Satan's spawn back in place. Ill update in a few days to report what the deal is.On a more PCM based note. Im now running EFILive custom OS5. It works fine and takes OS3 calibrations. Basically it extends OS3 by adding switchable timing and fueling for NOS applications. You could also use it to pull timing based on a switch for fuel octane variances.

It also supports Alpha-n fueling which is purely determined by Throttle and RPM, no other inputs such as MAF or MAP etc are used. Its really designed for hellish cams that wont hold or give a vacuum or stable airflow reading. (I wish that was me!)

So Ill be likely making some comments on that in the future given thats now my PCM OS d'jour. So its goodbye to OS3 and hello to OS5.

Monday, June 19, 2006

More idle thoughts

It seems that the question of a smooth idle comes up more than almost any other question when tuning. Especially with aftermarket camshafts etc.

I guess when cruising in closed loop with the MAF just about anything will work. This is due to how closed loop feedback from the O2 sensors and the Mass AirFlow meter work. It really takes the guesswork out of tuning. No doubt exactly why GM use it.

Well throw a cam in there and when starting cold the car will be in open loop and at low rpm speed density airflow calculations come into play.

That sorts out those with good tunes from those that just do the easy stuff.

Anyway following on from those thoughts, Ive done a load of changes recently which threw my tune out. Just spent the morning dialing it back in. Now its nice again. (For the next day anyway)

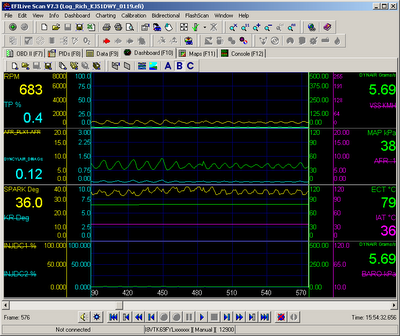

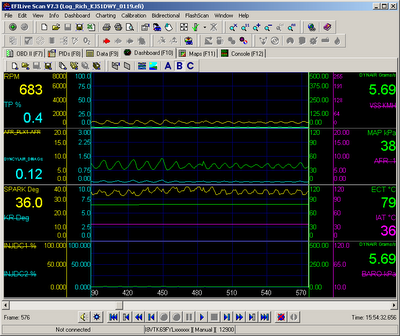

Take a look at this first image, it shows the idle hunting up and down, spark, vacuum, rpm and if it was shown, IAC counts basically wavering to and fro. If it gets bad enough it will stall. Sometimes the oscilations will increase and get worse. Often when AC is turned on or the Radiator fans startup.

So all in all, it idles, but its horrible. Ok so how do we normally fix this? First we go back to basics and make sure that the engine is getting enough air at idle, or at least getting what it wants. To do this we log both short and long term idle corrections to airflow. These corrections are made by the PCM to try and get a stable idle. In efilive they are known as calculated pid's as they are summed and made into a single value for easy logging. So we make a map with ECT vs the RAFIG pid (Only this is needed for M6 cars, Auto's use RAFPN as well) as the car heats up it will log a map of adjustments required to the Desired Airflow table. Once warmed up, we shutdown and update this table. If you cant get your car to idle initally, you might need to start logging to figure out which way its going and just guess to get it to run long enough to map the adjustments.

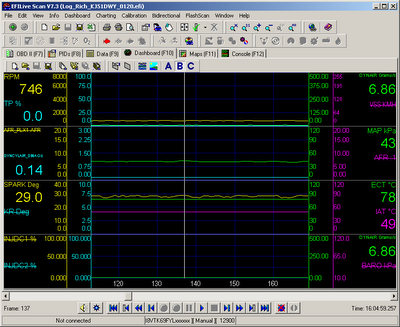

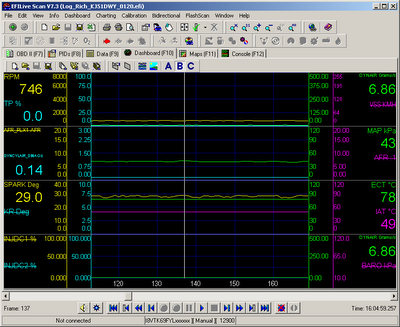

So once the airflow is updated. Its worth going into the bidirectional controls utility to see if adjusting the spark and fuel mix would help the idle. In my case fuel was ok (set to 15:1 at idle) but spark was now quite a bit out. Dropping it from around 38 degrees to 28 degree's sorted out a lot of the hunting. Im assuming the new injectors and injector offset tables I have been messing with caused some of this. So easy done, all fixed. Now back to a smooth idle. I just made sure my high octane table and base spark tables were close in the idle and off idle areas, so that transitions were smooth between both tables and all is well. The resulant logs are shown below. Notice RPM is now almost dead flat and there is some slight adjustment to spark by the PCM to hold it there.

So there we go. A short run down on tuning idle for anyone who is having issues in this area.

So there we go. A short run down on tuning idle for anyone who is having issues in this area.

I guess when cruising in closed loop with the MAF just about anything will work. This is due to how closed loop feedback from the O2 sensors and the Mass AirFlow meter work. It really takes the guesswork out of tuning. No doubt exactly why GM use it.

Well throw a cam in there and when starting cold the car will be in open loop and at low rpm speed density airflow calculations come into play.

That sorts out those with good tunes from those that just do the easy stuff.

Anyway following on from those thoughts, Ive done a load of changes recently which threw my tune out. Just spent the morning dialing it back in. Now its nice again. (For the next day anyway)

Take a look at this first image, it shows the idle hunting up and down, spark, vacuum, rpm and if it was shown, IAC counts basically wavering to and fro. If it gets bad enough it will stall. Sometimes the oscilations will increase and get worse. Often when AC is turned on or the Radiator fans startup.

So all in all, it idles, but its horrible. Ok so how do we normally fix this? First we go back to basics and make sure that the engine is getting enough air at idle, or at least getting what it wants. To do this we log both short and long term idle corrections to airflow. These corrections are made by the PCM to try and get a stable idle. In efilive they are known as calculated pid's as they are summed and made into a single value for easy logging. So we make a map with ECT vs the RAFIG pid (Only this is needed for M6 cars, Auto's use RAFPN as well) as the car heats up it will log a map of adjustments required to the Desired Airflow table. Once warmed up, we shutdown and update this table. If you cant get your car to idle initally, you might need to start logging to figure out which way its going and just guess to get it to run long enough to map the adjustments.

So once the airflow is updated. Its worth going into the bidirectional controls utility to see if adjusting the spark and fuel mix would help the idle. In my case fuel was ok (set to 15:1 at idle) but spark was now quite a bit out. Dropping it from around 38 degrees to 28 degree's sorted out a lot of the hunting. Im assuming the new injectors and injector offset tables I have been messing with caused some of this. So easy done, all fixed. Now back to a smooth idle. I just made sure my high octane table and base spark tables were close in the idle and off idle areas, so that transitions were smooth between both tables and all is well. The resulant logs are shown below. Notice RPM is now almost dead flat and there is some slight adjustment to spark by the PCM to hold it there.

So there we go. A short run down on tuning idle for anyone who is having issues in this area.

So there we go. A short run down on tuning idle for anyone who is having issues in this area.

Saturday, June 17, 2006

Radiant

Well today was a mixed bag of events, a badly secured clip that held the IAT sensor in the intake came off and meant that the sensor dropped on the drive belt stripping a few cords off it and causing it to drop off. All this about 70 miles outside of London. I didnt have any tools so ended up with the recovery guy putting what was left of the belt back on.

I couldnt find the metal clip which had secured the IAT inside the air intake so thought Id just check where it went.. Yep, it was lodged at the back of the manifold near cylinders 7 & 8. The guy hooked it out with a magnet and all was well.

Suffice to say metal clips arnt going back in there. The rubber gromit the intake had come with was a bad fit so I need to sort something reliable out.

So that cancelled my trip as I didnt want to get stranded in Wales and have to leave my car there if I couldnt get a replacement belt, so back home I went. I managed to get a new belt and fitted that right away.

At this point things got better as I decided that I would then fit my new injectors and thermostat.

I didnt have a fuel rail removal tool, which is pretty essential to get them off so just followed some info on www.ls1howto.com, pulling the fuel pump relay cranking the engine to dump the line pressure then removing it. Suffice to say even though there was no pressure there is still a lot of fuel in there and you will get it everywhere, so make sure you have a rag.

Pulling the old injectors out of the manifold is easy, but they are well stuck in the fuel rail. All of them took a bit of effort to pull out and left their rubber seals in the rail. Once removed the new ones went in nicely with a little bit of petrolium jelly. Here is a pick from halfway though.

Note the IAT and MAF sensor connectors are now tied away with tape too after the earlier mornings troubles!

Next was the 160*F thermostat. All in, both jobs only took a couple of hours. I set the fans to come on around 80*C and the high speed fans around 87*C. To celebrate I also pushed timing up 3% across the board.

So a flash of the changes, including rescaling the injectors with RedHardSupra's injector table and I was away. Immediately I noticed VE was up to 10% out. Cool I thought, it did need more timing. I added around 5%, but then remembered some comments on Injector Offset. Basically the larger injectors are lazier at low duty so need more time to open etc. Joe who posts on efilive had posted some new tables which had worked well for him so I have used that as a starting point and will do some more logging and check to make sure that all that extra fuel is required. Hopefully it is and the consequence is more power. Knock is not appreciably increased over what it was before, that is, a tick now and again but no sustained knock under load. Only really there on throttle tip in.

So only exahust upgrade to go, some final tuning and off to the dyno. Also time for a few gtech runs I think.

I couldnt find the metal clip which had secured the IAT inside the air intake so thought Id just check where it went.. Yep, it was lodged at the back of the manifold near cylinders 7 & 8. The guy hooked it out with a magnet and all was well.

Suffice to say metal clips arnt going back in there. The rubber gromit the intake had come with was a bad fit so I need to sort something reliable out.

So that cancelled my trip as I didnt want to get stranded in Wales and have to leave my car there if I couldnt get a replacement belt, so back home I went. I managed to get a new belt and fitted that right away.

At this point things got better as I decided that I would then fit my new injectors and thermostat.

I didnt have a fuel rail removal tool, which is pretty essential to get them off so just followed some info on www.ls1howto.com, pulling the fuel pump relay cranking the engine to dump the line pressure then removing it. Suffice to say even though there was no pressure there is still a lot of fuel in there and you will get it everywhere, so make sure you have a rag.

Pulling the old injectors out of the manifold is easy, but they are well stuck in the fuel rail. All of them took a bit of effort to pull out and left their rubber seals in the rail. Once removed the new ones went in nicely with a little bit of petrolium jelly. Here is a pick from halfway though.

Note the IAT and MAF sensor connectors are now tied away with tape too after the earlier mornings troubles!

Next was the 160*F thermostat. All in, both jobs only took a couple of hours. I set the fans to come on around 80*C and the high speed fans around 87*C. To celebrate I also pushed timing up 3% across the board.

So a flash of the changes, including rescaling the injectors with RedHardSupra's injector table and I was away. Immediately I noticed VE was up to 10% out. Cool I thought, it did need more timing. I added around 5%, but then remembered some comments on Injector Offset. Basically the larger injectors are lazier at low duty so need more time to open etc. Joe who posts on efilive had posted some new tables which had worked well for him so I have used that as a starting point and will do some more logging and check to make sure that all that extra fuel is required. Hopefully it is and the consequence is more power. Knock is not appreciably increased over what it was before, that is, a tick now and again but no sustained knock under load. Only really there on throttle tip in.

So only exahust upgrade to go, some final tuning and off to the dyno. Also time for a few gtech runs I think.

Friday, June 16, 2006

Refinement

Got my 160* 'stat today and SVO's

Also playing about with Base Spark and High Octane tables. I think Im getting a little jerkyness due to low throttle positions swapping between both tables. Especially when hardly touching throttle. I have made both tables a little closer in value to see how that goes. Its possible its DFCO messing with things too, though often the RPM value appears below the DFCO enable point.

So a long trip tomorrow, then sunday, thermostat installation day. I think Ill take the spark plugs out too and clear off the corners as recommended by Vizard. Im hoping to be able to push spark up by around 10% across the board. We will see. I have 21 at WOT and 19.5 at Peak Torque which is very similar to my stock tune, so I guess thats not too bad. KR is almost non existent. As I think I mentioned earlier these heads will need less timing anyway. So maybe 22-24 deg is optimal.

I need to sort out the exhaust gaskets as Im getting some cat bypass pipes done up and they need the gasket to make the flanges up. I think Ill go 2.5->3.5->2.5 so that the 3.5 section acts as a resonator and terminates the collector length. Otherwise it will be 2.5 from the headers way back to the current resonators, which from my reading appears too far. Though Ill have to measure up to be sure.

So the current series of mods is coming to an end. Soon it will be time to go and see whats up on the Dyno.

Also playing about with Base Spark and High Octane tables. I think Im getting a little jerkyness due to low throttle positions swapping between both tables. Especially when hardly touching throttle. I have made both tables a little closer in value to see how that goes. Its possible its DFCO messing with things too, though often the RPM value appears below the DFCO enable point.

So a long trip tomorrow, then sunday, thermostat installation day. I think Ill take the spark plugs out too and clear off the corners as recommended by Vizard. Im hoping to be able to push spark up by around 10% across the board. We will see. I have 21 at WOT and 19.5 at Peak Torque which is very similar to my stock tune, so I guess thats not too bad. KR is almost non existent. As I think I mentioned earlier these heads will need less timing anyway. So maybe 22-24 deg is optimal.

I need to sort out the exhaust gaskets as Im getting some cat bypass pipes done up and they need the gasket to make the flanges up. I think Ill go 2.5->3.5->2.5 so that the 3.5 section acts as a resonator and terminates the collector length. Otherwise it will be 2.5 from the headers way back to the current resonators, which from my reading appears too far. Though Ill have to measure up to be sure.

So the current series of mods is coming to an end. Soon it will be time to go and see whats up on the Dyno.

Tuesday, June 13, 2006

Exhausting

After removing most restrictions with the new heads, cam, intake system etc I have now turned my sights on the exhaust system.

I spend some time with a tape measure and clamp measuring the diameter of the various parts of the exhaust system.

Well its not too good. The cat back looks ok, 2.5". The headers are ok, ending up in try-y configuration with a 2.5" exit. The problem then is the 2" pipe into the cats with the O2 sensor in there too! Thats less than 3.14" sq area compared to the rest at 4.9" sq for the 2.5" section. It will even be less due to the O2 sensor in there. Now if I knew what I was doing with calculating exahust flow Id be able to verify that the exahust is a restriction. Though I have read another Vizard article which states dual 2.5" exahust will support up to 500bhp without restriction. So based on my hope to be at around that level at the flywheel the exhaust is going to be a restriction with its 2" bit, so out it goes.

My options are to replace the cat system with a bypass pipe for "off road use". This will allow me to replace it for "road use" and emissions testing. Hopefully I dont forget to replace it and just leave the offroad pipes on :)

As per usual good old Mr Vizard has an excellent article on exhaust selection and design here.

From what I understand the main summary is that exhaust tuning can produce up to 500% increase in cylinder scavanging over what the usual induction stroke of the 4 stroke cycle produces. Primary header length is not as important as collector length, and wise placement of open chamber or resonator boxes helps to terminate the effective collector length. A good rule of thumb is 2.2cfm of exhaust flow per engine bhp. So a 500bhp engine requires 1000cfm of exhaust. In addition a 1"sq pipe flows around 115cfm. So from this I can see my 2"sq pipe will only flow around 350cfm, or a total of 700cfm (2 pipes) a 50% increase in exahust flow is required to remove the current restriction! And worse because both 2" pipes have an O2 sensor blocking half of it off!

So anyway looking at options now, which include replacement headers as well. I think this is going to have to be the end of the purchasing mission. Finances have taken a hammering recently so hopefully there will be no mechanical restrictions, or at least only minor ones. (Like not having a Fast90/90 setup!) Still waiting for the thermostat and injectors. Im pretty sure the 30lb SVO's will be ok as Im not at 100% duty with the 28's yet. Unless the replacement exhaust makes this change a lot then I should be fine. RedHotSupra has recommended 42lb injectors as they will fit more nicely at the 80% level. In retrospect this is likely to be correct. However the 30lb ones should be ok, but will sit at a higher level.

Still aiming at 400rwhp

I spend some time with a tape measure and clamp measuring the diameter of the various parts of the exhaust system.

Well its not too good. The cat back looks ok, 2.5". The headers are ok, ending up in try-y configuration with a 2.5" exit. The problem then is the 2" pipe into the cats with the O2 sensor in there too! Thats less than 3.14" sq area compared to the rest at 4.9" sq for the 2.5" section. It will even be less due to the O2 sensor in there. Now if I knew what I was doing with calculating exahust flow Id be able to verify that the exahust is a restriction. Though I have read another Vizard article which states dual 2.5" exahust will support up to 500bhp without restriction. So based on my hope to be at around that level at the flywheel the exhaust is going to be a restriction with its 2" bit, so out it goes.

My options are to replace the cat system with a bypass pipe for "off road use". This will allow me to replace it for "road use" and emissions testing. Hopefully I dont forget to replace it and just leave the offroad pipes on :)

As per usual good old Mr Vizard has an excellent article on exhaust selection and design here.

From what I understand the main summary is that exhaust tuning can produce up to 500% increase in cylinder scavanging over what the usual induction stroke of the 4 stroke cycle produces. Primary header length is not as important as collector length, and wise placement of open chamber or resonator boxes helps to terminate the effective collector length. A good rule of thumb is 2.2cfm of exhaust flow per engine bhp. So a 500bhp engine requires 1000cfm of exhaust. In addition a 1"sq pipe flows around 115cfm. So from this I can see my 2"sq pipe will only flow around 350cfm, or a total of 700cfm (2 pipes) a 50% increase in exahust flow is required to remove the current restriction! And worse because both 2" pipes have an O2 sensor blocking half of it off!

So anyway looking at options now, which include replacement headers as well. I think this is going to have to be the end of the purchasing mission. Finances have taken a hammering recently so hopefully there will be no mechanical restrictions, or at least only minor ones. (Like not having a Fast90/90 setup!) Still waiting for the thermostat and injectors. Im pretty sure the 30lb SVO's will be ok as Im not at 100% duty with the 28's yet. Unless the replacement exhaust makes this change a lot then I should be fine. RedHotSupra has recommended 42lb injectors as they will fit more nicely at the 80% level. In retrospect this is likely to be correct. However the 30lb ones should be ok, but will sit at a higher level.

Still aiming at 400rwhp

Tuesday, June 06, 2006

Yay my first planned mod has finally arrived

Super cool awsome. My otrcai has arrived. Can you notice it in this photo?

It was made white for me by efi dynamics in Melbourne Oz. Thanks to Les also from ls1-australia for organising it for me. I chose white so it reflected the heat as much as possible. I might even put some silver reflective tape on the bottom. Might help it resist heat soak a little. Should be worth an extra 50bhp, what do you think!? Ok well maybe 0.1bhp anyway.

It was made white for me by efi dynamics in Melbourne Oz. Thanks to Les also from ls1-australia for organising it for me. I chose white so it reflected the heat as much as possible. I might even put some silver reflective tape on the bottom. Might help it resist heat soak a little. Should be worth an extra 50bhp, what do you think!? Ok well maybe 0.1bhp anyway.

I had to take a sliver off the neck so it fitted back far enough for the bonnet to close. Nice and snug, so its not going anywhere. Did a test drive up the road. Definately makes more power. Some good sideways action at the round about to check and back home. I have a reasonable drive coming up thursday and an even longer one at the weekend so Ill get some good logging done.

Well new injectors 30lb Ford SVO's (yes I said Ford) are shipped. They should give me plenty of head room and are accepted as a good choice for heads and cam vehicles that need a little more injector capacity. Stock 26lb ones are only good for stock engines. The later 28.8lb ones are ok with mild cam only. But I logged a 92% duty the other day and that was still under 6000rpm so definately need more. The Ford ones rate around 36lb on the GM pumps due to higher pressure, this should be good for around 650bhp based on my understanding of BSFC, which admitedly is probably pretty shocking.

BSFC as I understand is the engines ability to turn fuel into power. A more efficient engine will get more power from each lb of fuel. Forced induction engines are good, as are some high compression NA engines. Take a look here for Mr Wikipedia's take on the matter.

Ok so now I shouldnt be intake restricted any more. Thermostat will help keep engine and combustion temps under control so I can get a little more timing.

I did a traction limited 0-100 of 5.6sec the other night. Not so brilliant. But that was my first go. I will run a few more times and practice my launch etc. I think I might be able to get it to very low 5's and will some luck and probably more tuning even under 5!

Also today I messed with a number of tuning tables in order to arrest my reverse full lock low speed stall. It appears totally fixed now. Cool. I might celebrate by dropping idle down a little to 780 from 800 and see how it goes. It will idle at 700 rpm, but is a little tetchy about doing so. I think 780 might be good enough.

It was made white for me by efi dynamics in Melbourne Oz. Thanks to Les also from ls1-australia for organising it for me. I chose white so it reflected the heat as much as possible. I might even put some silver reflective tape on the bottom. Might help it resist heat soak a little. Should be worth an extra 50bhp, what do you think!? Ok well maybe 0.1bhp anyway.

It was made white for me by efi dynamics in Melbourne Oz. Thanks to Les also from ls1-australia for organising it for me. I chose white so it reflected the heat as much as possible. I might even put some silver reflective tape on the bottom. Might help it resist heat soak a little. Should be worth an extra 50bhp, what do you think!? Ok well maybe 0.1bhp anyway.I had to take a sliver off the neck so it fitted back far enough for the bonnet to close. Nice and snug, so its not going anywhere. Did a test drive up the road. Definately makes more power. Some good sideways action at the round about to check and back home. I have a reasonable drive coming up thursday and an even longer one at the weekend so Ill get some good logging done.

Well new injectors 30lb Ford SVO's (yes I said Ford) are shipped. They should give me plenty of head room and are accepted as a good choice for heads and cam vehicles that need a little more injector capacity. Stock 26lb ones are only good for stock engines. The later 28.8lb ones are ok with mild cam only. But I logged a 92% duty the other day and that was still under 6000rpm so definately need more. The Ford ones rate around 36lb on the GM pumps due to higher pressure, this should be good for around 650bhp based on my understanding of BSFC, which admitedly is probably pretty shocking.

BSFC as I understand is the engines ability to turn fuel into power. A more efficient engine will get more power from each lb of fuel. Forced induction engines are good, as are some high compression NA engines. Take a look here for Mr Wikipedia's take on the matter.

Ok so now I shouldnt be intake restricted any more. Thermostat will help keep engine and combustion temps under control so I can get a little more timing.

I did a traction limited 0-100 of 5.6sec the other night. Not so brilliant. But that was my first go. I will run a few more times and practice my launch etc. I think I might be able to get it to very low 5's and will some luck and probably more tuning even under 5!

Also today I messed with a number of tuning tables in order to arrest my reverse full lock low speed stall. It appears totally fixed now. Cool. I might celebrate by dropping idle down a little to 780 from 800 and see how it goes. It will idle at 700 rpm, but is a little tetchy about doing so. I think 780 might be good enough.

Friday, June 02, 2006

I thought so

A day spent on and under the car again today.

Some new NGK-BKR6E-11 plugs, well cheap I think about £12 all up shipped to my door. They are shorter than the stock Autolite plugs so will create less compression and run cooler. I pushed timing 0.5 degree up to celebrate and no KR was logged so things are heading the right way. Cold air intake and Thermostat to come.

I also ported my throttle body today. Here is the pic, a little blurry, but there you go.

An excellent writeup here on how to do this. I cancelled the BBK one I ordered, everyone says there is no point upgrading unless you go for a Fast90/90 setup.

Also here is a pic of the old plugs I pulled out. Ive done some spark plug research and Im guessing they looked a little lean/hot. But within acceptable limits. Take a look here for an excellent link on spark plug reading. New plugs are gasketed, which is the recommended plug for the darts. So plugs are now as they should be. The old ones have been consigned to the spares basket.

I also found a small exhaust leak, which was the likely reason my girlfriend was complaining the car was making her sick, "worse than before". And there I was thinking it was my driving all along, or the increased power and whiplash etc.

I also found a small exhaust leak, which was the likely reason my girlfriend was complaining the car was making her sick, "worse than before". And there I was thinking it was my driving all along, or the increased power and whiplash etc.

So good progress, slight increase in power and hopefully more to come with the remaining parts.

If you havnt done so already PORT YOUR THROTTLE BODY! Its easy and rewarding.

Last fuel fill the distance remaining read 420 Miles, which is pretty good, same as prior to heads and cam upgrade. So there you go a nice small port high flowing head with good compression and a mid-ish size cam can get you good street manners, more speed/power and retained economy.

Just a little by the way. The Dart heads have about 0.100 less valve clearance over stock heads. So notching pistons is more likely with the Darts. The valve springs are good to 0.620 but the drop wont support that with out compatible pistons.

Some new NGK-BKR6E-11 plugs, well cheap I think about £12 all up shipped to my door. They are shorter than the stock Autolite plugs so will create less compression and run cooler. I pushed timing 0.5 degree up to celebrate and no KR was logged so things are heading the right way. Cold air intake and Thermostat to come.

I also ported my throttle body today. Here is the pic, a little blurry, but there you go.

An excellent writeup here on how to do this. I cancelled the BBK one I ordered, everyone says there is no point upgrading unless you go for a Fast90/90 setup.

Also here is a pic of the old plugs I pulled out. Ive done some spark plug research and Im guessing they looked a little lean/hot. But within acceptable limits. Take a look here for an excellent link on spark plug reading. New plugs are gasketed, which is the recommended plug for the darts. So plugs are now as they should be. The old ones have been consigned to the spares basket.

I also found a small exhaust leak, which was the likely reason my girlfriend was complaining the car was making her sick, "worse than before". And there I was thinking it was my driving all along, or the increased power and whiplash etc.

I also found a small exhaust leak, which was the likely reason my girlfriend was complaining the car was making her sick, "worse than before". And there I was thinking it was my driving all along, or the increased power and whiplash etc.So good progress, slight increase in power and hopefully more to come with the remaining parts.

If you havnt done so already PORT YOUR THROTTLE BODY! Its easy and rewarding.

Last fuel fill the distance remaining read 420 Miles, which is pretty good, same as prior to heads and cam upgrade. So there you go a nice small port high flowing head with good compression and a mid-ish size cam can get you good street manners, more speed/power and retained economy.

Just a little by the way. The Dart heads have about 0.100 less valve clearance over stock heads. So notching pistons is more likely with the Darts. The valve springs are good to 0.620 but the drop wont support that with out compatible pistons.

Thursday, June 01, 2006

Another learning experience

Ok, so in hindsight (which is often the way these things get found out) Id have been better with a slightly lower compression setup. Im still confident that I can make do with my current setup with the mods mentioned above, but Im right on the edge. Timing is such that knock is not an issue. Its just not ideal for power.

So today I ordered the 160deg thermostat from Summit. In addition some serious WOT action today showed that my new slightly higher rated injectors wernt going to cut it as they were running 97% duty. With the new intake and hopefully additional timing which should require a little more fuel to get back to commanded fuel ratios Ill require some extra headroom. Actually the recommended headroom is to aim for 80% duty cycle anyway. Stock early LS1's are almost at 100% off the showroom floor! Anyway the reason I mention this is that I got some Ford SVO 30lb injectors. They will work out at around 36lb with the GM 4bar fuel pump and give lots of headroom.

I thought seeing as I was at it I might as well order a BBK 80mm throttlebody as well. The budget is now seriously blown and expenditure needs to be trimmed right back as things are getting out of control. Hopefully I can restrain myself and not buy a new exhaust system. The current one is ok, twin 2.5" but has cats and 2 mufflers on it. I need to pass emissions and see what my margin for error is. Hopefully it may allow the removal of the cats and while Im at it one of the mufflers. That might help airflow through the engine as well. Im currently running 0.85g/cyl which is about 0.07g/cyl off what Id expect (0.92g/cyl) Im hoping timing, throttlebody and cai will get me closer.

So today I ordered the 160deg thermostat from Summit. In addition some serious WOT action today showed that my new slightly higher rated injectors wernt going to cut it as they were running 97% duty. With the new intake and hopefully additional timing which should require a little more fuel to get back to commanded fuel ratios Ill require some extra headroom. Actually the recommended headroom is to aim for 80% duty cycle anyway. Stock early LS1's are almost at 100% off the showroom floor! Anyway the reason I mention this is that I got some Ford SVO 30lb injectors. They will work out at around 36lb with the GM 4bar fuel pump and give lots of headroom.

I thought seeing as I was at it I might as well order a BBK 80mm throttlebody as well. The budget is now seriously blown and expenditure needs to be trimmed right back as things are getting out of control. Hopefully I can restrain myself and not buy a new exhaust system. The current one is ok, twin 2.5" but has cats and 2 mufflers on it. I need to pass emissions and see what my margin for error is. Hopefully it may allow the removal of the cats and while Im at it one of the mufflers. That might help airflow through the engine as well. Im currently running 0.85g/cyl which is about 0.07g/cyl off what Id expect (0.92g/cyl) Im hoping timing, throttlebody and cai will get me closer.

Subscribe to:

Posts (Atom)